Product IntroductionAiming at the world's high-end, Beijing Shougang Jitaian New Materials Co., Ltd. developed the first ultra-high temperature iron-chromium-aluminum pipe in China in June 2020, e···

Product Introduction

Aiming at the world's high-end, Beijing Shougang Jitaian New Materials Co., Ltd. developed the first ultra-high temperature iron-chromium-aluminum pipe in China in June 2020, ending the history of domestic iron-chromium-aluminum materials wireless and pipe-free, and keeping up with the world-class level in the field of electric heating alloys. Ultra-high temperature iron-chromium-aluminum tubes use powder metallurgy methods to produce powder raw materials, and then produce billets through modern processes such as high-temperature hot isostatic pressing, followed by hot-rolled tube blanks and precision machining, and finally form electric heating alloy pipes with bright surface and accurate size.

SGHT uses refined master alloys as raw materials and powder metallurgy technology to manufacture alloy ingots, which are manufactured by special hot and cold working and heat treatment processes. The product has the advantages of strong oxidation resistance, good high temperature corrosion resistance, small creep of electric heating elements, long service life at high temperature, and small resistance change. It is suitable for high temperature 1425°C, high power density, corrosive atmosphere, carbon atmosphere and other working environments. It can be used in ceramic furnaces, high-temperature heat treatment furnaces, laboratory furnaces, electronic industry furnaces and diffusion furnaces.

Product Specifications:

1.Diameter of round wire φ: 0.1-8.5mm

2.Flat strip thickness d: 0.5-2.5mm width l: 5-48mm

3.Tubular finished product

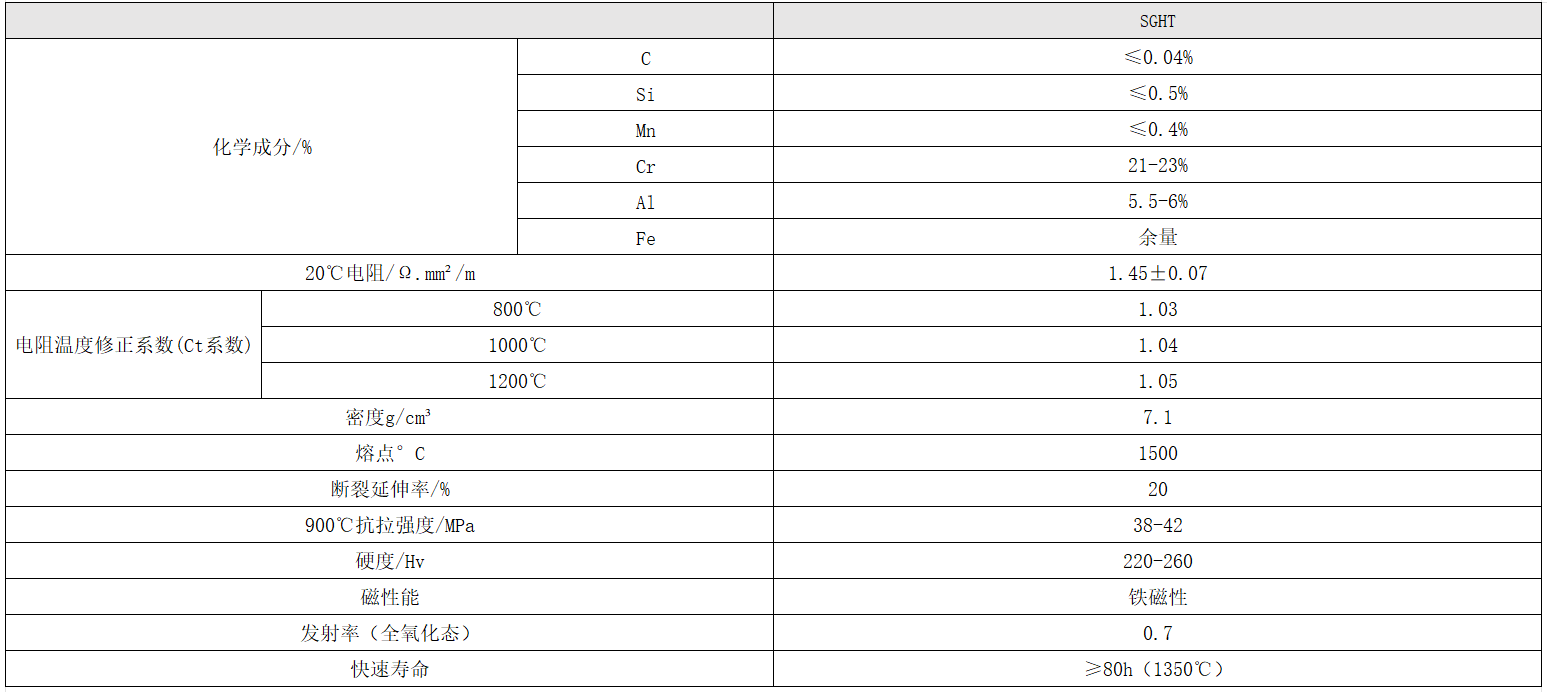

Basic parameters

Application direction

Ceramic furnaces, high-temperature heat treatment furnaces, laboratory furnaces, electronic industry furnaces and diffusion furnaces

Component performance

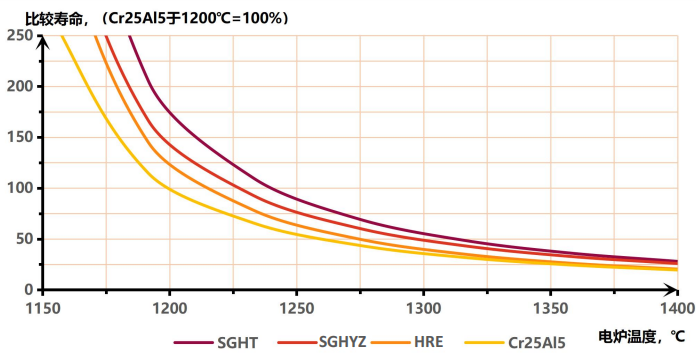

The rapid test life is the life of the alloy sample wire measured according to the rapid test standard and method under laboratory conditions. China continues to use the former Soviet Union to evaluate the cumulative time of power supply for 2min, power outage for 2min until burnout, and the sample specification is 0.8mm. Generally, the alloy with a long service life is also long in real life.

Tel: +86-510-86890852

Fax: +86-510-86267050

Phone: +86 18936076151

WhatsApp: 8618936076151

Add: NO. 345 YANXIN ROAD,HUISHAN DISTRICT, WUXI, JIANGSU, CHINA